A magneto coil, also known as an ignition coil, is vital in generating the high voltage necessary for spark plug ignition. By conducting a thorough multimeter test, you can determine whether the magneto coil is functioning correctly or requires repair or replacement. How to test a magneto coil with a multimeter?

“Set your multimeter to the resistance or ohms setting. Disconnect the spark plug wire from the coil. Place the multimeter’s positive (red) lead on the coil’s primary terminal and the negative (black) lead on the coil’s secondary terminal. Read the resistance value displayed on the multimeter. If the reading is within the manufacturer’s specified range, the coil will likely function correctly. If the reading is significantly higher or lower, the coil may be faulty and require replacement”.

What are Magneto Coils?

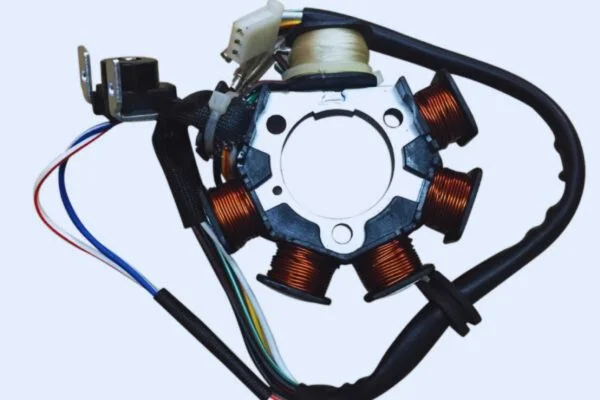

Magneto coils, also known as ignition coils, are essential components of small engine ignition systems. They are responsible for converting low voltage from the battery into high voltage required to create a spark at the spark plug.

The spark, in turn, ignites the air-fuel mixture, powering the engine. Understanding the function and importance of magneto coils is critical to diagnosing ignition system issues.

Read more aboutHow to Test a Pickup Coil with Multimeter?

Signs of a Faulty Magneto Coil

Identifying the signs of a faulty magneto coil can help determine if testing is necessary. Some common indicators of a problematic magneto coil include a weak or inconsistent spark, engine misfires, difficulty starting the engine, or a complete lack of spark. If you encounter any of these issues, it’s crucial to investigate the magneto coil’s condition to ensure smooth engine operation.

Compatibility and Replacement Considerations

When testing a magneto coil, it’s crucial to consider compatibility and the availability of replacement parts. Magneto coils come in various types and designs, and each engine model may require a specific coil type. Consult the engine manufacturer’s guidelines or documentation to ensure you test and replace the magneto coil with the correct one suitable for your engine’s make and model.

Seeking Professional Help

While this guide will equip you with the knowledge and skills to test magneto coils, it’s worth noting that complex ignition system issues may require professional assistance.

If you encounter difficulties during the testing process or suspect other underlying problems, consulting a certified mechanic or small engine specialist can provide valuable expertise and ensure a proper diagnosis and repair.

Safety Precautions

Safety should be your top priority before learning How to test a magneto coil with a multimeter? Some pro-safety precautions are given, have a look:

Importance of Safety Measures

Safety should always be a top priority when working with electrical components like magneto coils. Taking necessary precautions ensures your well-being and reduces the risk of accidents or damage to the equipment. By following these safety measures, you can conduct the testing process with peace of mind.

Power Off and Disconnect

Before beginning work on the magneto coil, power off the engine and disconnect the spark plug wire. This step prevents accidental ignition and protects you from potential electric shocks. Always double-check that the machine is completely turned off before proceeding.

Protective Gear

Wearing appropriate protective gear is essential when working with electrical components. Consider wearing insulated gloves and safety glasses to protect yourself from potential hazards. These protective measures provide an additional layer of protection against electrical shock or debris that may be generated during the testing process.

Multimeter Safety

When using a multimeter, ensure it is in good working condition and suitable for the voltage range you will be testing. Follow the manufacturer’s instructions for proper usage and avoid touching the metal probes while the multimeter is powered on.

Remember to set the multimeter to the appropriate range and function before testing the magneto coil.

Work in a Well-Ventilated Area

Testing the magneto coil in a well-ventilated area is essential to avoid inhaling potentially harmful gases or fumes. Conduct the testing outdoors or in a well-ventilated workshop. Adequate ventilation helps dissipate any gases emitted during testing, providing a safer environment.

Handle with Care

While testing the magneto coil, handle the components with care and avoid applying excessive force. Magneto coils are delicate and can be easily damaged if mishandled. Treat them gently to ensure accurate testing results and to avoid unnecessary expenses for replacement.

Tools and Materials

Here are some significant tools and materials are given which will be helpful in testing. So, these steps are:

The Multimeter: Your Essential Tool

The multimeter is a crucial tool for testing magneto coils. It measures electrical properties such as voltage, resistance, and continuity. Ensure you have a reliable multimeter suitable for automotive use and capable of handling the voltage range required for testing magneto coils.

Read more about 5 Best Budget Auto Ranging Digital Multimeter

Additional Tools

In addition to the multimeter, gather a few other tools to assist you during the testing process. These may include a socket set or wrenches to disconnect the magneto coil, wire strippers or pliers for any necessary wire manipulation, and a clean cloth or alcohol wipes for cleaning the multimeter probes and coil contacts.

Magneto Coil Documentation

Refer to the engine manufacturer’s documentation or service manual for the specific requirements for testing the magneto coil.

The documentation can provide valuable insights into the testing process, including the recommended voltage range and procedures unique to your engine model.

How to test a magneto coil with a multimeter? Learn quickly just in 5 steps

I will provide you with simple and easy steps on how to test a magneto coil with a multimeter. So have a look:

Step 1: Disconnecting the Magneto Coil

Start by powering off the engine and disconnecting the spark plug wire. This ensures your safety and prevents accidental ignition during the testing process. Use a socket set or wrench to disconnect the magneto coil from the engine carefully.

Step 2: Preparing the Multimeter

Set your multimeter to the appropriate function for testing resistance or continuity. Refer to the multimeter’s user manual if you need clarification on the settings. Ensure the multimeter leads are clean and in good condition, as dirty or damaged leads can affect the accuracy of the test results.

Read more aboutMultimeter symbols and what they mean ?

Step 3: Testing the Continuity of the Primary Winding

Identify the primary winding terminals on the magneto coil. Place the multimeter probes on these terminals, ensuring a secure connection.

The multimeter should display a reading indicating continuity if the primary winding is intact. If there is no continuity, it suggests a problem with the primary winding.

Step 4: Testing the Resistance of the Secondary Winding

Locate the secondary winding terminals on the magneto coil. Connect the multimeter probes to these terminals, ensuring they are firmly attached. The multimeter should display a resistance value within the specified range for a healthy magneto coil.

If the resistance value is significantly higher or lower, it indicates a fault in the secondary winding.

Step 5: Interpreting the Test Results

Based on the test results, you can determine the condition of the magneto coil. The magneto coil will likely function correctly if the primary and secondary windings show continuity and resistance within the specified ranges. However, if there is no continuity or the resistance values are out of range, it suggests a faulty magneto coil that requires repair or replacement.

Troubleshooting Common Issues

Once you have conducted the magneto coil test, analyzing the results is essential to troubleshoot potential issues. So, some common problems are discussed here:

- If there is no continuity in the primary winding test: This indicates a break or open circuit in the primary winding. The magneto coil may need to be replaced.

- If there is no continuity in the secondary winding test: This suggests a fault in the secondary winding, possibly due to a short or open circuit. Consider replacing the magneto coil.

- If the resistance values are significantly higher or lower than the specified range: This indicates an issue with the winding’s resistance. A damaged wire or insulation may cause it. In such cases, replacing the magneto coil is usually recommended.

- If the resistance values are out of range: Check for any damaged or frayed wires causing abnormal resistance readings. Ensure proper insulation and connections. If the issue persists, replacing the magneto coil is advisable.

FAQs about How to test a magneto coil with a multimeter

How do you diagnose a bad magneto?

Diagnosing a bad magneto can be done through a series of tests. First, check for any visible signs of damage, such as cracks or burns on the coil or other components. Next, use a multimeter to measure the resistance of the coil. A healthy magneto coil should have a specific resistance value within the manufacturer’s specifications. If the resistance is significantly outside the acceptable range or reads as an open circuit, it indicates a faulty coil.

Additionally, check for proper spark output by grounding the spark plug against the engine and observing the spark while cranking the engine. If there is no spark or it is weak and inconsistent, it suggests a problem with the magneto. However, it’s important to note that magneto systems vary, and consult the manufacturer’s guidelines for specific troubleshooting steps is recommended.

What voltage is a magneto coil?

The voltage generated by a magneto is typically around 50 volts. However, with the assistance of a coil, this voltage can be dramatically increased. The coil boosts the voltage to an impressive 15,000 volts. The coil acts as a step-up transformer, utilizing electromagnetic induction to amplify the voltage output of the magneto. This heightened voltage is often necessary to ignite the spark plugs in internal combustion engines, enabling combustion and powering various devices.

What causes magnetos to fail?

Magnetos, those nifty devices that power the ignition in small engines, can sometimes go kaput. But fear not, my friend, for I’ll explain what may lead to their downfall. One common culprit is good ol’ wear and tear. Over time, the internal components of a magneto can experience fatigue and break down. Moisture, that sneaky troublemaker, can also wreak havoc by corroding the delicate parts.

Another mischievous factor is improper maintenance, like attention to routine inspections and cleanings. And let’s not forget the notorious electrical gremlins—faulty connections or damaged wiring can make a magneto wave the white flag too. So, my friend, keep an eye out for these mischief-makers and show your magneto some tender, loving care to keep it humming with joy.

Conclusion

Hopefully, you can tell others how to test a magneto coil with a multimeter now. Maintaining magneto coils will help you with the ignition system. You’ve got to keep safety in mind when working with electrics.