Want to learn How To Check Alternator Without Multimeter? If you’re a car enthusiast, you know the importance of regularly maintaining and checking your alternator. An alternator regulates the current in your vehicle, ensuring that your battery remains properly and providing power to essential components such as headlights, starter motors, horns, etc.

But how do you check whether an alternator works correctly without using complex tools? At first glance, it may appear daunting, but with our step-by-step guide on how to check alternators without a multimeter, it couldn’t be simpler! Read on to learn more about our definitive guide which will help you identify any problems in seconds and save money too!

Table of contents

What Is An Alternator?

An alternator is an electrical generator used in modern cars and other automobiles. It helps to generate electricity by rotating an armature in a magnetic field, producing alternating current energy. Alternators provide the main power source for all electrical components in most automobiles. Although includes interior lights, climate control systems, radio, wiper motors, starter motors, and air conditioning systems.

What Does It Do In A Car Engine?

Alternators are typically more efficient than generators because they use less engine power and deliver more electric output. The alternator generates electricity while the car runs and stores it in battery cells. It may be available even when the engine isn’t running or additional power is needed due to accessories being switched on simultaneously, such as heated seats or climate control systems being activated simultaneously.

The typical size of an automotive alternator can range from 60 Amps to 130 Amps capacity depending on vehicle model and make. Generally speaking, alternators offer higher charge rates with improved efficiency compared to battery-powered charging systems. Since they are always actively generating current from belt-driven sources like camshafts or crankshafts while moving through swift rotations of pulleys revolving around them.

How To Check Alternator Without Multimeter | Step-by-Step Procedure

The alternator is an integral part of your vehicle’s electrical system and plays a major role in ensuring the efficient operation of all its components. Knowing how to check its condition without a multimeter can help you identify potential problems early on and keep your car running smoothly for longer.

Step 1: Engine Warm-up and Accessory Shutdown“

First, you must start the engine and let it idle for several minutes. This allows the alternator to charge up after being inactive for so long, activating any sensors needed for testing. Once it has been running for about five minutes, turn off all accessories that require electricity, such as headlights or air conditioning systems. These draw power away from the battery, which could interfere with accurate readings later.

Step 2: Terminal Identification and Voltage Test

Now open the hood of your car and locate both terminals found at either end of the alternator’s body. Typically designated ‘B+’ (battery positive) and ‘B-‘ (alternator negative). The contacts should be easy to spot as plastic covers often protect them with labels next to them indicating their function.

Check these two points against each other using a voltage meter set to DC mode. If available, make sure no current flows between them before continuing further. This usually means that the charging system isn’t working properly or is overcharging itself, needing immediate attention from an auto-shop specialist!

Step 3: Thorough Proximity Inspection for Faults

Inspecting other parts within proximity, such as wiring harnesses or fuses connected directly, can sometimes uncover faults within various components until their final connection point at B+ & B-. Spotting loose connections, cuts into a wiring insulation material, etc., can save lots of time.

Whenever trying to resolve more serious issues concerning electronics repairs/replacement on vehicles – plus avoiding expensive diagnostic tests ordered by mechanics unnecessarily!

Step 4: Precise Voltage Measurement on Terminals

Once satisfied, everything looks in order with regard to external visual checks. Then proceed to measure voltage output through each terminal respectively: ‘B+’ should produce 14v while ‘B-’ should be producing anywhere between 8v & 12v depending upon manufacturer specifications applicable. If one reads higher than the other, then double-check again because this might indicate trouble within the circuitry internal!

Step 5: Engine Rev Test for Abnormal Noises

Lastly, listening intently but carefully near each contact when revving the engine slightly may reveal abnormal noises from the inside unit itself. It indicates faulty conductivity; however, don’t put yourself too close to danger due risk of exposure to high voltages present during the procedure 🙂

We hope this clarifies how you can perform proper checks without necessarily requiring access to special diagnostics tools normally found only in workshops specializing in complex auto repairs today – happy motoring fellow reader(s)!

If you’re looking for the best budget multimeters then, click here.

How To Test Alternator Using A Multimeter | Step By Step Procedure

To test an alternator, a multimeter or voltmeter can be used to measure the alternator’s output voltage at different engine speeds. It is important to remember that the alternator’s charging system requires a running engine for proper operation. So it must be tested with the engine running. If you’re looking for a quality multimeter for alternator testing then click here!

Step 1:

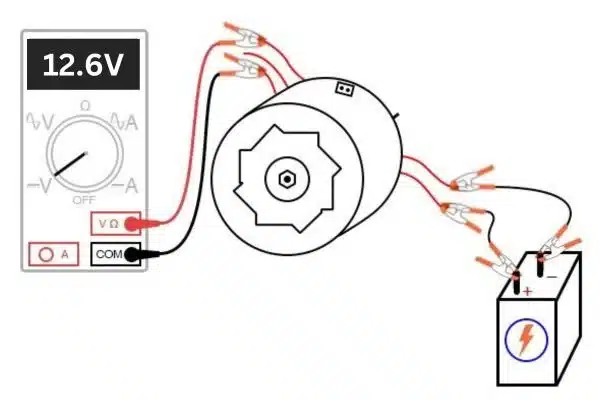

Begin by cleaning any dirt or debris from around the battery capacity and terminals. This will ensure good contact between them when measuring voltage. Connect one lead of your multimeter/voltmeter to the positive terminal on your battery. Then connect another lead to a ground point near your engine, such as an exposed metal surface on the vehicle frame.

Step 2:

Set your car in neutral gear, allowing it to idle at normal speed (~1000 RPM). Once you have established consistent idle speed, note what is displayed on your meter. This should be close to 14 volts, indicating that your charging system is working correctly. If this value exceeds 15 volts,

There may be an overcharging issue present; if below 12 volts. Then likely, you are not getting enough charge out of that particular alternator circuit (which could indicate either bad diodes in its rectifier bridge circuits, insufficient RPMs for its field coil excitation, or other related faults).

Step 3:

Turn off all electrical accessories, such as air conditioning, lights, and audio systems. Further, test the alternator’s ability to increase or maintain output under load conditions. Turn up RPMs gradually from 1000RPM until 2500RPM (this process should take about 2-3 minutes). Observe changes in meter readings throughout this period.

If greater than 16V readings appear after approximately 2000 RPMs. Then chances are you’ve got high field current being sent into the rotor. Thus forcing excessive amounts of electricity back through external connections causing possible damage to coil/regulator circuits post-alternator upgrade, may also result in higher than expected values!

Step 4:

Lastly..you can also check the integrity of both stator windings & diode bridges by setting continuity mode following the manufacturer’s instructions. Also, using the ohmmeter counterpart provided within digital meters is popular today (generally has two leads connected to separate points such as those found corresponding positions, etc.).

This process allows the user to compare resistance readings. Before and after energizing the subject component – look for any significant deviation numbers indicating potential fault area(s) requiring repair attention!

Common Symptoms Of A Bad Alternator

The alternator is a key component of your vehicle’s charging system. That keeps the battery charged and powers all electrical components. A bad alternator can cause several different symptoms throughout your car.

Some of the most common symptoms of a bad alternator include dimmed or flickering headlights, dead battery, strange noises from the engine bay, and rapid battery discharging when running multiple electrical devices. Other signs that could indicate you have a failing alternator are:

1. Electrical failure in-vehicle systems

If you notice that none of your electronic components, such as radio, power windows, locks on doors, etc., are working. This could indicate something wrong with your charging system or possibly even your battery.

2. Warning lights on the dashboard

Many vehicles have warning lights built in that will indicate problems with their charging systems (typically called “Battery” or “Charging System”). Once illuminated, these lights tell drivers to inspect their battery and related parts for potential problems.

3. Loss of power while driving

If you find yourself losing acceleration while driving at a constant speed. Then it could be caused by a faulty alternator as it may not be providing enough current to keep up with demand from all other accessories being used in the car, such as audio equipment and air conditioning/heating etc, simultaneously

4. Strange smells emanating from the engine bay

A burning smell coming from underneath the hood indicates something is overheating inside due to a lack of proper cooling levels provided by an insufficient voltage output from failing Alternators.

Thus causing higher internal temperatures within its various components leading to premature breakdowns & malfunctions, in turn, emitting a unique odor indicating its presence. Thus prompting for immediate attention & repair by qualified mechanics/technicians thereof

5 Pulsating Headlights / Dashboard Lights

This usually occurs when the Alternators ability to convert mechanical energy into electrical energy goes haywire resulting in interrupted supply and leading towards intermittent operations like pulsations seen directly onto the dashboard & headlamps, making one aware of its failure situations before the total shutdown takes place, thereby saving time during repairs.

Replacement Cost Of An Alternator

When researching the cost of replacing an alternator, it can vary greatly depending on factors such as the make and model of your vehicle. Spending a few extra dollars upfront for quality. The professional alternator can go a long way down the line, saving you time and money in repairs or parts replacement.

Knowing what type of car you have helps narrow your search for the best value for your vehicle. Shopping around for varied prices from repair shops or parts stores is recommended. Additionally, read up on customer reviews from previous consumers before making a purchase.

Bottom Line

How To Check Alternator Without Multimeter? While a multimeter is the best way to test your alternator, it’s not the only way. You can also use an ammeter or a voltmeter to check the output of your alternator. If you don’t have a multimeter, you can still perform a basic Alternator Test by starting your car and disconnecting the negative battery terminal.

With the engine running, remove the nut that holds the positive cable to the alternator post. Touch the end of the red jumper cable to this exposed post, then touch the other end to any bare metal on your engine (you may want to wear gloves). You know your alternator has an issue if your engine stalls or dies.