Most of Auto-technicians don’t know how to test a wheel speed sensor with a multimeter? These sensors are vital for the anti-lock braking system (ABS) in modern vehicles. They provide crucial data on wheel rotational speed, optimizing braking performance and preventing wheel lock-ups. Regular testing ensures accurate and reliable sensor functionality.

Testing a wheel speed sensor with a multimeter is simple. “First, set the multimeter to voltage or resistance mode. Then, locate the sensor and disconnect its connector. Connect the multimeter’s probes to the sensor pins. Turn on the ignition and spin the wheel. Watch the multimeter for a steady reading. No reading or inconsistent values could mean a faulty sensor.” Stay safe and consult the vehicle’s manual for specific specifications.

In this article, I will discuss everything you need to know and provide some common testing issues. So, First of all, you need to understand what is speed sensor and how it works, so let’s go to the learning.

What is a wheel speed sensor?

A wheel speed sensor is a crucial component in modern vehicles that helps monitor the rotational speed of each wheel. Its primary function is to gather data and send it to the vehicle’s anti-lock braking system (ABS) or traction control system (TCS).

Read more about How To Test An Abs Sensor With A Multimeter?

The sensor is typically positioned near the wheel, detecting the toothed or magnetic wheel speed ring as it rotates. As the ring passes the sensor, it generates an electrical signal converted into digital information.

How does the wheel speed sensor work?

This information is transmitted to the vehicle’s computer system, which analyzes it to determine if any wheels are slipping or locking up. Based on this data, the ABS or TCS system can selectively apply braking pressure to individual wheels, ensuring optimal traction and preventing skidding or loss of control.

In essence, the wheel speed sensor acts as a vigilant guardian, monitoring wheel movement and facilitating timely interventions to maintain stability and enhance safety on the road.

Types of Wheel Speed Sensors

Vehicles commonly use two-wheel speed sensors:

- Magnetic inductive sensor

- Hall effect sensor

The magnetic inductive sensor relies on a toothed wheel or a tone ring with magnetic properties. In contrast, the Hall effect sensor uses a magnet and a semiconductor to detect wheel speed.

Read more about How To Test ABS Sensor With Multimeter?

Impact of Faulty Wheel Speed Sensors

Faulty wheel speed sensors can harm the overall performance of the ABS and compromise vehicle safety. The ABS may not function properly if a sensor fails to provide accurate speed data or sends erratic signals.

This can reduce braking effectiveness, longer stopping distances, and potentially dangerous situations during sudden or slippery road conditions.

Read more about: How To Test The Crankshaft Sensor With A Multimeter?

Preparing for the Testing Wheel Speed Sensor

Before discussing how to test a wheel speed sensor with a multimeter, it is essential to make the necessary preparations. Here are the key steps to ensure a successful testing procedure:

Gather the Required Tools

You will need a few essential tools and equipment to perform the test. Make sure you have a multimeter capable of measuring voltage and resistance and the vehicle’s service manual or documentation for reference. Keep a notepad and pen handy to record the measurements and observations during the test.

Ensure Safety First

Before starting any work on the vehicle, prioritize safety. Park the vehicle on a level surface and engage the parking brake. If necessary, use wheel chocks to prevent the vehicle from rolling. It is also advisable to wear safety glasses and gloves to protect yourself from any potential hazards.

Inspect the Sensor and Wiring

Inspect the wheel speed sensor and its wiring connections for any signs of damage or wear. Look for loose or corroded connectors, frayed wires, or physical damage to the sensor. If you notice any issues, address them before proceeding with the test. Furious wiring or damaged sensors can lead to accurate test results.

Familiarize Yourself with the Multimeter

If you still need to become familiar with using a multimeter, take a moment to review its functions and settings. Ensure the multimeter is set to the appropriate voltage and resistance measurement ranges for the wheel speed sensor test. Refer to the multimeter’s user manual for guidance if needed.

Read more about: How to Test a Speed Sensor with a Multimeter?

How to test a wheel speed sensor with a multimeter? A Step-by-Step Guideline

Now that you are prepared let’s dive into the step-by-step process of testing a wheel speed sensor using a multimeter. Follow these instructions carefully to accurately assess the sensor’s functionality and diagnose potential issues.

Step 1: Identifying the Wheel Speed Sensor

Start by locating the wheel speed sensor you want to test. It is usually positioned near the wheel hub or brake assembly. Refer to the vehicle’s service manual or documentation for specific guidance. Take note of the sensor’s physical appearance and any distinguishing features.

Step 2: Preparing the Multimeter

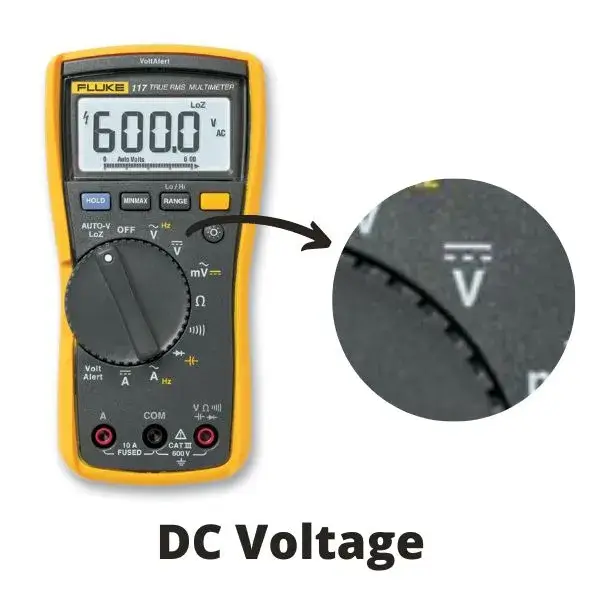

Set the multimeter to the appropriate measurement ranges for voltage and resistance. Typically, you must select the DC voltage measurement mode and a suitable range, such as 0-20 volts. For resistance measurement, choose the resistance mode and a range appropriate for the expected sensor values.

Step 3: Testing the Sensor’s Wiring

Disconnect the electrical connector from the wheel speed sensor. Using the multimeter, measure the resistance across the sensor’s terminals. Touch the multimeter’s probes to the corresponding terminals of the sensor connector. A healthy sensor typically shows a resistance value within a specified range mentioned in the vehicle’s documentation.

Step 4: Checking the Sensor’s Output Voltage

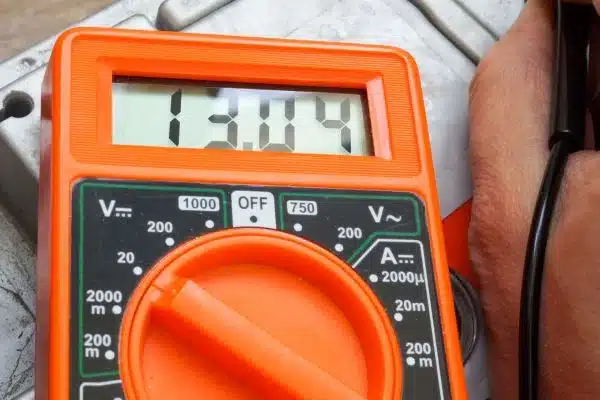

Manually rotate the wheel that corresponds to the sensor you are testing. Observe the multimeter readings as you rotate the wheel. The multimeter should display a voltage output from 0.5V to 1.0V that varies as the wheel rotates. This indicates that the sensor generates the appropriate signal based on the wheel’s speed.

Step 5: Inspecting the Sensor for Physical Damage

Carefully examine the wheel speed sensor for any signs of physical damage, such as cracks, corrosion, or broken wires. If you detect any damage, it is advisable to replace the sensor, as physical damage can affect its performance and accuracy.

Step 6: Repeating the Test (if necessary)

If the initial test results are inconclusive or questionable, you may need to repeat the test. Double-check the connections, ensure proper positioning of the multimeter probes, and perform the measurements again.

Further troubleshooting or professional assistance may be required if the readings need to be consistent or outside the expected range.

Interpreting the Results of Wheel Speed Sensor

It’s time to interpret the results after conducting the wheel speed sensor test using a multimeter. Understanding the significance of different outcomes will help you determine the sensor’s condition and take appropriate actions. Here’s how to interpret the results:

Normal Test Results

If the resistance measurement falls within the specified range mentioned in the vehicle’s documentation and the voltage output varies as the wheel rotates, congratulations! Usually, the voltage ranges are between 0.5-1.0 volts. These are positive indications that the wheel speed sensor is functioning correctly. You can proceed confidently, knowing that the sensor provides accurate speed data to the ABS.

Abnormal Test Results

Abnormal results can include resistance values outside the expected range or erratic voltage readings that do not correspond to wheel rotation. Such results may suggest underlying issues with the sensor or its wiring.

Further troubleshooting or professional assistance may be necessary to diagnose and resolve the problem effectively.

Inconclusive Test Results

Sometimes, the test results may be inconclusive, with borderline resistance values or inconsistent voltage readings. In such situations, it is advisable to repeat the test, ensuring proper connections and measurements.

If the readings remain inconclusive, consider seeking expert advice or consulting the vehicle’s service manual for additional guidance.

FAQs about how to test a wheel speed sensor with a multimeter

How many ohms is an ABS sensor?

An ABS sensor typically has a resistance value, measured in ohms, that varies depending on its design and specifications. However, it is essential to note that ABS sensors have no fixed or standard resistance across all vehicles. The resistance value can range from a few ohms to several hundred ohms.

It’s crucial to consult the specific manufacturer’s documentation or refer to the vehicle’s service manual to determine the precise resistance value for a particular ABS sensor. Remember, getting accurate information is key for smooth and efficient troubleshooting and repairs when it comes to automotive electronics.

What causes wheel speed sensor failure?

Wheel speed sensor failure can occur due to various reasons. One common cause is dirt or debris accumulation around the sensor, which can disrupt its ability to accurately detect wheel speed. Another factor is sensor wiring issues, such as fraying or corrosion, that can lead to faulty readings or complete failure.

Additionally, the sensor may suffer from internal damage or wear over time, resulting in inaccurate readings or complete malfunction. Regular maintenance, including cleaning and inspecting the sensor, can help prevent failure and ensure optimal performance of your vehicle’s anti-lock braking system (ABS) and traction control system (TCS).

Can you test a wheel speed sensor other than using a multimeter?

Certainly! While using a multimeter is a standard method to test a wheel speed sensor, there are alternative approaches you can try. One such method involves using a scan or diagnostic tool designed specifically for vehicle diagnostics. These tools can communicate with the vehicle’s onboard computer and retrieve the sensor’s data in real time.

Additionally, some modern vehicles have built-in self-diagnostic systems that can display error codes or warning lights when there’s an issue with the wheel speed sensor. Consulting your vehicle’s manual or seeking assistance from a qualified mechanic can help you explore these alternative testing methods. Remember, it’s always important to prioritize safety and consult professional guidance when dealing with vehicle components.

Conclusion

You now know how to test a wheel speed sensor with a multimeter. You should always put safety first before you test a speed sensor. With the right tools, you can save time and money. It’s recommended you get professional help if you need more clarification.