MOSFET is an acronym for Metal Oxide Semiconductor Field Effect Transistor. MOSFETs are the most popular transistor type and are used in a wide range of applications such as amplifiers, switching regulators, motor controls, and power supplies. In this article, I will discuss everything you need to know about MOSFETs including how to test them in a circuit!

So, if you don’t know how to test MOSFET in Circuit this guide is for you. But first, let’s have a look at MOSFET and their types.

What is a MOSFET?

The word MOSFET is derived from metal–oxide–semiconductor field-effect transistor as the name suggests it is an advanced transistor made up of metal oxide and semiconductor. It can be either n-channel or p-channel type. MOSFETs are unipolar devices because they consist of only one kind of charge carrier, electrons or holes.

MOSFETs are used in a variety of applications such as Amplifiers, Switches, Motor controls, Power supplies, Inverters and many other home appliances.

How do MOSFETs Work?

The operation of a MOSFET is based on the movement of charge carriers in the semiconductor. When a MOSFET is turned ON, the electric field generated by the gate terminal repels the carriers in the semiconductor. This creates a low-resistance path between the source and drain terminals, allowing current to flow through.

When a MOSFET is turned OFF, the electric field generated by the gate terminal attracts the carriers in the semiconductor. This creates a high-resistance path between the source and drain terminals, preventing current from flowing through.

A Quick guide about how to test Mosfet with multimeter

So if you’re in hurry here is a quick take away to test mosfet with multimeter.

- Set multimeter to diode test mode (symbol: diode or arrow pointing towards a line).

- Disconnect power and discharge capacitors in the circuit.

- Identify MOSFET terminals: Gate (G), Drain (D), and Source (S).

- Connect the red probe to the Gate (G) and the black probe to the Source (S).

- Observe the multimeter reading – a good MOSFET should show a high resistance (Open circuit).

- Reverse the probe connection (red to S and black to G).

- The multimeter should now display a low resistance (Short circuit) indicating a functional MOSFET.

Note: Some MOSFETs have an internal diode, so the readings may slightly differ; refer to the datasheet for specific testing instructions.

There are two types of MOSFETs: n-channel and p-channel.

n-channel MOSFETs are made up of semiconductor material with n-type doping. The n-type doping creates an excess of electrons in the semiconductor.

p-channel MOSFETs are made up of semiconductor material with p-type doping. The p-type doping creates an excess of holes in the semiconductor.

Now that we know the basics of MOSFETs, let’s learn how to test them in a circuit.

How to Test MOSFET in Circuit?

The most authentic way to test a MOSFET is to test it with a multimeter. But sometimes if the damage is big MOSFET might not work at all and in that case, you might see burns or carbon deposition on the MOSFET. In that case, you need to replace the MOSFET.

Tools Required to test MOSFET in a Circuit

- Digital multimeter (Best multimeters for Electronics work)

- Some Alligator clips

- Nose Plier

Recommended Digital Oscilloscope

Digital Oscilloscope Fluke 179

Fluke 179  Klein mm720

Klein mm720

Testing Mosfet Transistor with a multimeter (Don’t Miss A Single Step)

Step#01

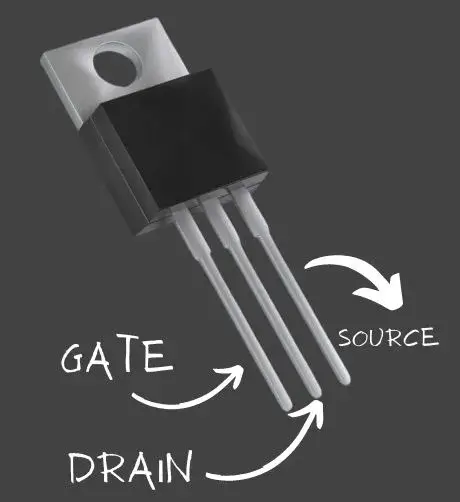

First of all, you need to identify the pins of the MOSFET. The gate terminal is always labeled with the letter “G”. The source and drain terminals are usually labeled with the letters “S” and “D”. The best way to identify these terminals is to see the MOSFET manufacturer datasheet.

Step#02

Now set the multimeter to diode mode and connect the positive lead of the multimeter to the gate terminal and the negative lead to the source terminal. The gate to source should have zero voltage. In the off position, the voltages must be zero, because the gate is insulated from the drain.

Step#03

Now do the same testing procedure between the gate and drain voltage terminals. You should see zero volts in the off position between the drain and gate voltage. This shows that the MOSFET is good.

Step#04

Now set the multimeter to resistance mode and connect the positive lead of the multimeter to the drain terminal and the negative lead to the source terminal. In the off position, you should see a high resistance between these terminals.

Step#05

Now turn on the MOSFET and touch probe to the drain and source terminals. You will see a low resistance. This shows that the MOSFET is good.

Step#06

Touch the black probe to the source, lift the red probe from the drain and touch it to the MOSFET gate momentarily, then return it to the drain. The meter must show continuity or you can say a short circuit here, meaning your MOSFET is good. If there is no continuity, then your MOSFET is bad.

This is the easiest method of checking defective MOSFETs. Because you can see the value of each terminal separately and conclude results accordingly.

Read More About: How to test Diodes with Multimeter

Steps to Test SMD MOSFET on a Circuit Board:

Step#01 | Identify the MOSFET:

Locate the SMD MOSFET on the circuit board.Identify the part number and datasheet for the MOSFET to understand its pinout and characteristics. Ensure the circuit is powered off before proceeding with the testing.

Step#02 | Determine Pinout:

Use the datasheet to identify the MOSFET’s pinout. Common pins include Gate (G), Drain (D), and Source (S).

Step#03 | Check for Short Circuits:

Use the multimeter to check for short circuits between the MOSFET pins. Place the probes on adjacent pins and check for continuity. There should be no short circuits.

Step#04 | Check Gate-Source Diode:

In diode testing mode, place the multimeter probes across the Gate (G) and Source (S) pins. The meter should show a diode drop (typically 0.5 to 0.7V) in one direction and open circuit in the reverse direction.

Step#05 | Check Drain-Source Diode:

Test the diode between the Drain (D) and Source (S) pins. Again, there should be a diode drop in one direction and open circuit in the reverse direction.

Step#06| Check Gate-Drain and Gate-Source Resistance:

Measure the resistance between the Gate (G) and Drain (D), as well as between the Gate (G) and Source (S). The resistance values should be very high, indicating an open circuit.

Step#07 | Check for Gate Capacitance:

If your multimeter has a capacitance measuring function, measure the capacitance between the Gate (G) and Source (S) pins. This value should be within the expected range according to the datasheet.

Step#08 | Functional Testing:

- If possible, power up the circuit and perform functional tests. Observe the behavior of the circuit, and check if the MOSFET is switching as expected.

- Compare the measured values with the specifications provided in the datasheet. This helps verify if the MOSFET is within its operational parameters.

Guarding Your MOSFETs: Detecting and Preventing Common Faults

A guide to preventing critical faults in your circuits. Improve circuit reliability with essential strategies for detecting and preventing MOSFET malfunctions.

Gate-Source Overvoltage Faults

Cause: Factors contributing to these faults include voltage spikes, electrostatic discharge (ESD), or transient events exceeding the gate-source voltage of the MOSFET.

Identification:

Oscilloscope Observation: Monitoring the gate-source voltage waveform with an oscilloscope is an important part of operating the gate. A sudden spike or irregular pattern could indicate an overvoltage.

Transient Voltage Suppressors (TVS): A transient voltage suppressor diode should be connected across the gate-source terminals. Transient overvoltages are protected from MOSFETs by these diodes.

MOSFETs may suffer from gate-source overvoltage faults, which could compromise the overall reliability of the device. The gate-source voltage can be easily tracked and protective measures can be taken to prevent these faults.

Gate Oxide Breakdown

Causes:

An excessive voltage exposure, gradual wear, or manufacturing defects can cause gate oxide breakdown.

Identification:

Increased Gate Leakage: A high gate leakage current may suggest compromised gate oxide integrity.

Voltage Monitoring: In order to ensure the gate-source voltage stays within safe limits, measure it against the specified limits on the MOSFET.

The degradation of MOSFET performance and potential circuit failure may occur as a result of gate oxide breakdown faults. The risks associated with gate oxide breakdown can be mitigated if you detect signs of increased leakage and carefully monitor voltage.

Avalanche Breakdown Faults

Causes:

Usually, these faults occur when the drain source voltage is excessive due to inductive loads, load switching, or other transient events.

Identification:

Voltage Monitoring: Use an oscilloscope to observe the drain-source voltage during load transitions. An avalanche breakdown might be indicated by voltage spikes.

Clamp Diodes and Snubbers: In order to suppress voltage spikes and protect the MOSFETs, use clamp diodes or snubber circuits.

MOSFETs can be damaged by avalanche breakdown faults over time. Using protective components and monitoring drain-source voltage, you can prevent these faults from damaging your circuit.

Substrate Diode Failures

Causes: Reverse voltage, improper biasing, and manufacturing defects can cause substrate diode failures.

Identification:

Reverse Voltage Testing: In order to identify whether the substrate diode is compromised, test for reverse voltage across the drain-source junction.

Diode Continuity Check: A multimeter can be used to check for continuity in the substrate diode.

MOSFET performance and circuit behavior can be adversely affected by substrate diode failures. You can spot and resolve these failures quickly by verifying reverse voltage and performing continuity checks.

Cross-Conduction Faults

Causes: Cross-conduction faults occur when both the high-side and low-side MOSFETs of a half-bridge circuit are conducting simultaneously due to insufficient gate drive overlap.

Identification:

Oscilloscope Analysis: Make use of an oscilloscope to examine the gate-source waveforms of both MOSFETs. When both MOSFETs are on at the same time, look for any overlapping periods.

Gate Driver Circuitry: To prevent cross-conduction, ensure proper gate driver circuitry with adequate dead time.

It is possible for cross-conduction faults to produce shoot-through currents and heat. Optimizing gate driver circuitry and analyzing gate-source waveforms can eliminate cross-conduction and improve circuit efficiency.

Safety Guide

Be careful while testing the MOSFET in a circuit as there is a high chance of damaging the MOSFET or multimeter if not done properly. Mosfets are used in power circuits so make sure you take all the safety precautions while testing MOSFETs.

- If you see any damage or burn then just replace it without testing as it is already damaged.

- Always use gloves and safety glasses while working with MOSFETs.

- Make sure you know the maximum voltage and current ratings of the MOSFET before testing it in a circuit.

- Never try to test a MOSFET with a multimeter if you are not sure about what you are doing. Always take help from an experienced person.

- Make sure that the probe tips of the multimeter are always clean. A dirty probe tip can damage the MOSFET.

- For safety measures you should also consult with an expert if you are new to this work.

Conclusion

Mosfets are just like transistors so the testing procedure is also similar. It’s like to be riskier to test a MOSFET in live circuitry so make sure you take all the safety precautions while testing MOSFETs. Both n-p-n and p-n-p-type MOSFETs can be easily tested with the help of a multimeter. If you see any damage or burn just replace it without testing as it is already damaged. I hope after reading this guide you may understand how to test MOSFET in-circuit helpful. Stay safe and keep learning. Thanks for reading!

Frequently Asked Questions

Why testing a MOSFET is important?

Testing a MOSFET is the most authentic way to check if it is working properly or not. It is also important to test a MOSFET before using it in a circuit as it can be damaged if not used properly. Most of the MOSFETs physically look perfect but they’re not. So, testing is the only way to be sure about its performance.

What are the voltages drops in “drain to source” and “gate and drain”?

The voltage drop in “gate to drain” should be zero and the voltage drop in “drain and source” should be high when the circuit is energized.

Why diode mode is used for testing a MOSFET?

In diode mode, the multimeter measures the voltage drop between two terminals. So, in order to test a MOSFET, diode mode is used to measure the voltage drop between the gate and drain terminals. If the voltage drop is zero, then the MOSFET is good.

Why you should use a Digital multimeter?

The most appropriate device to check electronics components in close and open circuit is a Digitial Multimeter. Because digital multimeter show gate, source and drain voltages in digital figure.

How to test a mosfet on a circuit board?

To test a MOSFET on a circuit board, measure its gate-to-source voltage (Vgs) with a multimeter while applying a suitable voltage to the drain (Vd) and source (Vs). Compare Vgs with the datasheet specifications to verify its operation. Ensure the MOSFET’s drain current (Id) doesn’t exceed its maximum rating to avoid damaging it.