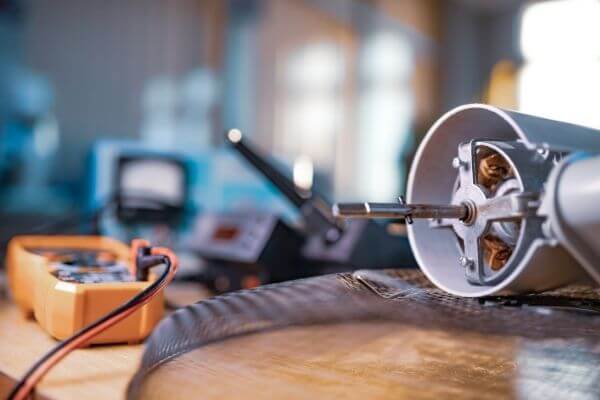

When a motor is being turned on, it can produce voltage that can cause serious injuries. The main purpose of the winding test is to see if the wires are broken or shorted while there is no power applied to the windings. With this testing method you will be able to find out possible causes of failure in your electric motors. Therefore, it is important to know how to check motor winding with multimeter.

What is a multimeter and why to use it?

Multimeter is an electrical testing device that basically has two parts: a meter and some connections. The meter part is used to measure voltage, current, and resistance. That’s why we will be using it for checking the winding on an electric motor. But before jumping on to testing you must know about motors and their working principles.

What is an electric motor and how does it work?

The working principle of an electric motor is based on the fact that when a wire carrying electric current passes through a magnetic field, it experiences force. This force causes the wire to move because of its natural orientation. Here, the wire is connected with some type of armature which causes rotational motion at high speed.

Types of Motors

- Synchronous motor: It works on the same principle, but uses electromagnets instead of permanent magnets. These are used in electric vehicles to improve performance and efficiency.

- Asynchronous motor: It runs on DC power source while synchronous motor does not require external power for starting. These are the most commonly industrial squirrel cage motors.

- Permanent Magnet Motors: This type of motor has a rotor that has permanent magnets. In this case, the armature is shorted to produce a torque.

- Brush or Direct Current Motors: It uses commutators or slip rings to transfer power from the source into the armature.

- Series-Wound Motor: Its a type of direct current motor that has a permanent magnet. It starts up fast and produces large torque.

- Universal Motor: The major components of the motor are fixed on a single shaft enabling it to operate on either AC or DC.

- Shaded-Pole Motor: It uses a laminated rotor to create a magnetic field that is equal in both directions. In this case, the stator poles are magnetized by external current.

- Stepper Motor: It is used to move a load in fixed increments, also called steps. In this case, the rotor moves forward or backward with each increment.

When applying a voltage to the circuit of an electric motor, it produces mechanical or kinetic energy. This is useful in many applications such as elevators, air conditioners, blowers, pumps etc. It comes in many shapes and sizes depending on the application it’s used for. But the basic principle of operation remains the same for all motors.

What are permanent magnet and Electromagnets?

The two types of windings are: Permanent magnets and electromagnets.

Electromagnet: The word itself explains how it works. An electromagnetic field is created by the flow of electric current through a coil to produce a magnet. When the current is turned off, the magnetic field disappears.

Permanent Magnet: These type magnets are made of either by aligning the magnetic domains in a piece of iron or other material that magnetizes easily. This type of magnet is permanent as their name suggests.

Now that we know about various kinds of electric motors and their working principle, let’s get started with the testing process.

How to test a DC motor?

There are basically three parts to an electric motor: the stator, the rotor and shaft. One thing you must know is that there can be nothing wrong with the windings and magnets of a sensor less brushless DC (BLDC) motor because it doesn’t use any windings. So, for this type of motor it’s not necessary to check the winding or magnets.

How to check motor winding with multimeter?

Step by Step guide to electric motor testing

1. First of all grip the motor securely while it is running.

2. Make sure that there is no power going to the motor before testing it.

3. There are two connections on a multimeter one with black and another with red color. Both have different functions, so be careful when using them on an electric circuit because they can do harm.

4. Set the multimeter to ohms and put one end of the black probe on a motor terminal or wire that you think is broken while trying to check the winding. The other red probe should go to another motor terminal. Now watch your meter, if it shows resistance then your wire is not shorted, but if there isn’t any resistance it shows a short circuit.

5. If the meter reads null make sure that you are testing with respect to ground, or else test with respect to “phase”, which is the power supply terminal of the motor. Make sure to try both ways for accurate results.

6. To check if windings have broken either go from a wire to a wire or from the wire to “phase” and check your multimeter readings. If they show open circuit then the windings are broken or disconnected in between them.

7. If you want to be sure after checking for short and open circuits, use a power supply of 12V and slowly increase its voltage up to 110VAC while checking your meter readings. If the meter reading increases with voltage then your windings are just fine.

8 Most common faults in electric motors and how to troubleshoot them

1. Short circuit:

The most commonly found fault, could be because of a pile up of dirt or grease on the surface of the motor. A simple cleaning with dry cotton cloth would solve this issue. If not, then use sandpaper to clean it thoroughly before testing for winding continuity again.

2. Open Circuit:

This is also a very commonly found fault. It mostly happens when wires inside the motor break and disconnect after years of use. This can be fixed by soldering them back together or in some worst cases re-winding.

3. Intermittent shorted winding:

When a wire breaks due to excessive pressure or heat this problem occurs. You will have to rewire it carefully without causing any further damage.

4. Noisy operation:

When a motor operates at high speed with an unusual noise, most likely one of its fan blades is damaged and needs to be replaced.

5. High temperature:

All motors, irrespective of their working voltage will work at high temperature if it isn’t ventilated properly. The only solution would be to improve its ventilation or replace it with an appropriate fan of good quality.

6. Overload:

This problem occurs only when a motor has been forced to operate continuously at or above its rated capacity, which could lead to serious damage to the motor and needs repair before it starts working again.

7. Noise:

A rumbling noise on start up indicates that there is some dirt accumulated inside the bearings and needs cleaning. A metallic noise shows that there is some problem with the fan and it should be replaced as soon as possible.

8. Temperature:

Don’t forget to check your motor’s operating temperature. Too much heat could lead to serious damage to the motor and you might end up wasting more money on repairs than buying a new one (if you don’t have all the equipment and experience required).

Conclusion:

As you have seen, how to check motor winding with multimeter is not that difficult. As long as you are patient and follow all steps carefully, there is nothing that can stop you from fixing any of these problems on your own. If your motor is running on VFD then you should also check your VFD. Therefore, I have also made a separate guide on how to test VFD with a multimeter.