How To Test VFD with Multimeter? If you’re an industrial technician then you must know about variable frequency drive, Converter, and inverter. Being an electronics engineer, troubleshooting VFD problems was always a challenge for me. So, after a lot of research and experience, here I will tell you how to test VFD with a digital multimeter. I have also made a list of 5 best multimeter for testing electronics for your ease. But before VFD troubleshooting, you must know about variable frequency drive.

What is a Variable Frequency Drive (VFD)?

“A Variable Frequency Drive (VFD) is a device used to control the speed of an electric motor. It is also used for energy savings because it reduces the motor torque. You can change the motor frequency by regulating its input power supply. A VFD has an inverter and converter.It has an AC to DC converter and DC to AC inverter. These converters and inverters are used as regulators to maintain the flow of current and frequency. Before buying any VFD you must know about its rated power otherwise you will face drive failure issues.Why Test a VFD?

A VFD is a critical piece of equipment in many processes and industries. It is important that a VFD is properly tested to ensure that it is operating properly. The process of testing a VFD includes verifying the correct input and output of voltage, frequency, and phase sequence.Parts of VFD

Before testing a VFD, it is important to understand the different parts of the drive. The following is a list of the most common parts of a VFD:Controller

The controller of the VFD is the main part of the VFD. It regulates all of the functions of the VFD. Drive- The drive is the part of the VFD that converts the AC voltage to DC voltage. It also converts the DC voltage back to AC voltage. rectifier-Rectifier Diode

The rectifier diode is the part of the VFD that converts the AC voltage to DC voltage.Capacitor Bank

A capacitor bank is used to absorb excess voltage from the motor when the VFD changes the frequency. The capacitors store the charge until it is needed by the drive. They’re also used as filters on DC bus, which provides clean DC voltage.IGBT

The IGBT is a semiconductor device for power conversion. It has three terminals- Collector, Base, and Emitter. In VFD, it is used to convert DC voltage to AC voltage.How to test VFD with multimeter?

How To Test VFD with Multimeter? VFDs are rated with certain maximum frequencies, voltages, and amperage. A VFD’s performance is measured by the following:

- Input Frequency: The input frequency is the rate at which an AC voltage is applied to the VFD.

- Input Voltage: The input voltage is the voltage that is applied to the VFD.

- Output Frequency: The output frequency is the rate at which an AC voltage is output from the VFD.

- Output Voltage: The output voltage is the voltage that is output from the VFD.

- Amperage: The amperage is the maximum amperage that can be output by a VFD at maximum speed. A lower amperage may cause the motor to overheat.

Tools Required for troubleshooting VFD problems

Digital MultimeterScrewdriver setPower supplySteps by step guide of variable frequency drives testing

Troubleshooting and Testing Drive in Energize/live condition

To test drive in the live condition you must have to be very careful. You have to be a bit conscious when the power supply is connected.- The first step before checking any drive or motor is to measure the dc bus voltage. If the voltages are in-between 450 to 750 then it’s ok. But if the voltage drop below 450V then there might be an issue with your dc capacitors.

- If you see any variation in power then must check terminals. Because in VFD most of the faults occur due to losing of connection. If you’re facing issues in power supply testing then you can visit my blog.

- You can not open a VFD in live condition. So, check all control cables and power cables connections. Hopefully, it can solve the problem. Check the cooling fan is working properly if yes then note the temperature it must be under 85 degrees celsius. I have also compiled a list of best multimeters to check temperature. If the issue still prolong then you have to shut down the drive and open it.

Troubleshooting and Testing Drive in Idle condition

To test a VFD for input and output voltage, frequency, and phase sequence:- Disconnect the input power to the VFD.

- Remove the cover of the VFD.

- Locate the drive input and output rails of the VFD.

- Now connect motor at drives output terminals.

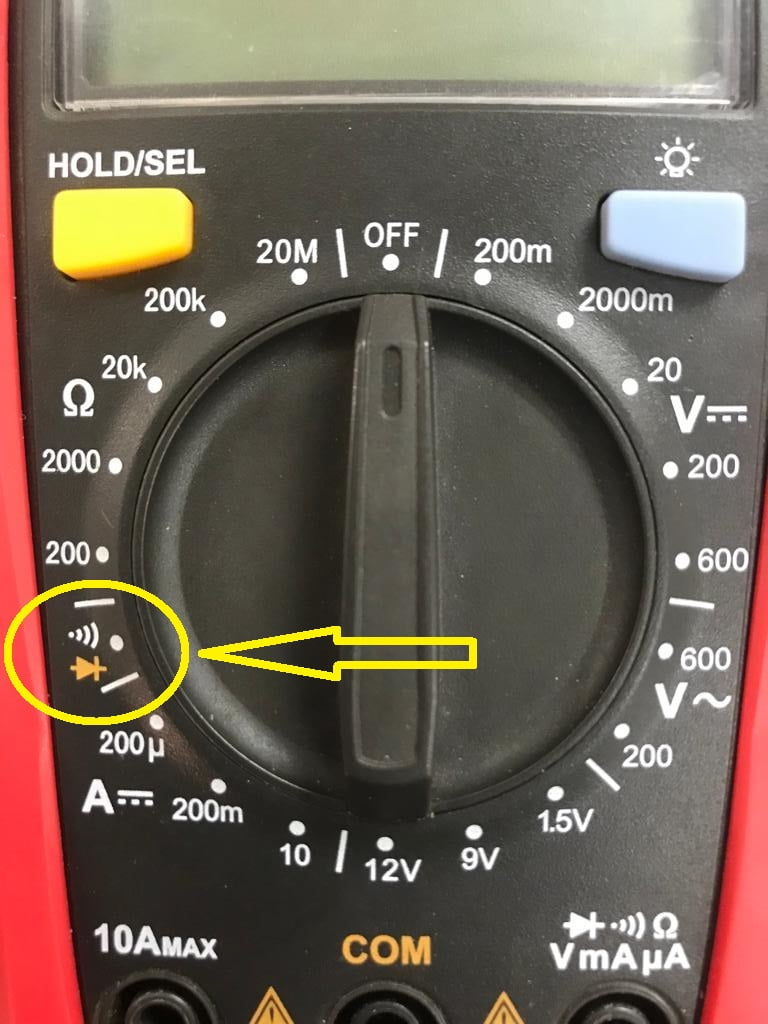

- Set the multimeter to continuity function and place the red lead of multimeter on each phase of input and the black lead on the VFD body. If there is minute resistance or interpreted beep then it means the drive is fine. If it beeps strongly higher then it means the diode/bridge rectifier is faulty or any short circuit at inputs. You can also perform a diode check test by diode check function of your digital multimeter.

- After measuring the resistance and continuity of input components you should test terminals of the output side. Normally Output side is indicated as U, V, W or U2, V2, W2. If the motor is connected to drive then all the outputs will show continuity due to motor windings. Otherwise, it will show infinite resistance.

- If you face any current unbalance then immediately stop the drive and find the root cause. Sometimes C.T at the output side of VFD also gives you current unbalance results. So, it’s better to replace the C.T or its driving card.

- Caution this is only for professionals: If you haven’t found the fault yet then all you have to do is open the drive mark the tags take photos of all connections. After taking photos take out the IGBT and Diode from the drive and do a bench test. If you want to know about bench testing of diode and IGBTs then it’s very simple. Hopefully one of them will be faulty. Now replace it.

- If the IGBTs and Diodes are good then please call your customer care provider for further help. Because the problem might be in the program or in the control card.

How do I know if my VFD is bad?

The motor drives on VFD will stop functioning or run in an abnormal manner. You can also check the output voltage of the drive to check its status. There can be any fault in your VFD but the following are the most common faults of VFDs.- shorted IGBT,

- Current unbalance

- terminal scaling

- meter reads OL (overload)

- Faded display

- Short circuit in the inverter section

- DC bus overvoltage

- DC bus under voltage

- Colling Fan failure

Safety Guide

Almost every VFD manufacturer provides customer support and an extensive user manual to operate it. In the user manual, you will find some common wiring diagrams, Alarm indications, and fault codes with descriptions.Things to do

- Never touch the dc bus voltage with the AC range. The multimeter will explode.

- Always use an auto-ranging multimeter with CAT-II standard test leads to check dc bus voltage.

- Your multimeter should have a dc current measurement function. If you’re not sure which multimeter should you buy then I have made a complete guide about it.

- Always wait minimum 5 minutes before opening terminal connections

Things no to do

- Never connect full load motor with respected drive.

- Troubleshooting variable frequency drives and motors

- Never touch input or output terminals while testing drive.

Reasons To Test VFD with Multimeter

A Variable Frequency Drive (VFD), also known as an inverter, is a device that controls the speed of an AC motor by manipulating the frequency and voltage of its power supply. While VFDs are robust pieces of equipment, they can malfunction like any other electronic device. A multimeter, a handy tool for measuring electrical properties, can be a valuable asset in troubleshooting potential VFD issues. Here are some key reasons to test a VFD with a multimeter:

1. Initial Power and Basic Functionality Checks

Input Power Verification: A basic check involves measuring the AC line voltage at the VFD’s input terminals. This ensures the VFD is receiving the correct voltage for proper operation.

Control Circuit Functionality: While a multimeter can’t directly diagnose control circuit problems, you can check for continuity in control signal wires or measure voltage at specific points according to the VFD’s manual. This can help isolate issues like a faulty control board or keypad.

2. Troubleshooting Common VFD Faults

Input Rectifier Issues: The input rectifier converts AC voltage to DC voltage. A multimeter’s diode test function can be used to check individual rectifier diodes for open or shorted conditions.

DC Bus Voltage Measurement: The DC bus is a vital component within the VFD, storing the converted DC voltage. Using the DC voltage setting on your multimeter, you can measure the voltage level at designated test points. Deviations from the expected values might indicate problems in the rectifier or charging circuits.

Output Transistor Testing (Limited Capability): While a multimeter can’t definitively diagnose output transistor issues, you can perform basic diode tests on some transistor types to get a preliminary indication of potential problems. Refer to the VFD’s manual for specific testing procedures.

3. Investigating Motor Control Problems

Abnormal Motor Speed or Behavior: If the motor connected to the VFD is exhibiting erratic behavior or not responding to speed adjustments, you can check the DC bus voltage again. An abnormal voltage reading could point towards a problem with the VFD’s output stage affecting motor control.

Important Considerations When Testing a VFD with Multimeter

Multimeter Limitations: It’s crucial to understand that a multimeter has limitations when testing VFDs. The output voltage of a VFD is typically a Pulse Width Modulated (PWM) signal, which a standard multimeter might not accurately measure due to its averaging function. An oscilloscope is a more suitable tool for analyzing the waveform and identifying distortions that could indicate problems.

Safety Precautions: VFDs deal with high voltages and currents. Always ensure the VFD is disconnected from the power source before performing any measurements. Follow proper safety protocols and consult the VFD’s manual for specific instructions on safe testing procedures.

Consult the Manual and Seek Professional Help: The VFD manufacturer’s manual is an invaluable resource. It will provide specific information on the VFD’s expected voltage readings at various test points and any recommended testing procedures. If the multimeter readings suggest a problem beyond your expertise, don’t hesitate to seek help from a qualified electrician or VFD technician.

Frequently Asked Questions-FAQs

What is the aim of dc voltage at dc bus in VFD? How to use them?

The aim of DC bus connection at terminals is to check the status of the diode. You can also discharge the capacitors by these terminals. Secondly no you can not use them for DC load purposes.

How to test ABB VFD with a multimeter?

You can check any drive including ABB VFD with a multimeter. The only thing you have to do is read the blog and follow the instructions thoroughly. If you still can’t find a solution then you consult an ABB VFD expert. (usamashafiq41@gmail.com)How to check the power supply of VFD?

If you want to check the power supply of a VFD with a multimeter then I have written a complete blog on power supplies testing.Conclusion

While a multimeter isn’t a one-stop solution for diagnosing all VFD issues, it can be a valuable tool for initial checks, basic troubleshooting, and verifying power supply conditions. Remember, safety is paramount when working with VFDs. By using the multimeter appropriately, consulting the VFD manual, and understanding its limitations, you can gain valuable insights into the health of your VFD and identify potential problems for further investigation.