Do you know how to test IAT sensor with a multimeter? I will discuss three different parts of IAT sensor testing. IAT sensor technology is a revolution in the world of sensing and control.

If you want to test O2 Sensor with multimeter, you can read the my other blog.

Moreover, it combines three sensing technologies into one sensor, two temperature measurements, infrared absorption, and thermal conductivity. You can also learn How to Test a TPS Sensor with a Multimeter?

However, this technology has brought about many applications in many industries, from automotive to medical, with new possibilities for automation, data collection, and more. With its versatility and accuracy, IAT sensor technology is also an excellent choice for any sensing application.

Tools Required to Test IAT Sensor With Multimeter

- Digital Multimeter (DMM)

- Safety Glasses

- Gloves

- Wiring Diagram or Repair Manual

- Assistant

- Work Light or Flashlight

- Wrench or Screwdriver

How To Test IAT Sensor With A Multimeter?

How to test IAT sensor with a multimeter? Testing the IAT sensor is easy, but you must try 3 different parts. Let’s get started.

Read more about How to Test 3 Wire Cam Sensor with Multimeter?

Using a multimeter to test the resistance of an IAT sensor:

Step 1: Disconnect the Electrical Connector

The first step to testing your Intake Air Temperature (IAT) sensor is to disconnect the electrical connector. In this step, the vehicle’s electrical system is prevented from interfering with readings.

Step 2: Set Digital Multimeter to 50K Ohms

Use a Digital Multimeter with a 50K Ohm scale for accurate measurements. The resistance of the IAT sensor can be accurately assessed by this setting. However, if you have an auto-ranging multimeter then it will be a plus point. If you need some high-quality but budget-friendly automotive multimeters then you can visit my guide.

Step 3: Measure Terminal Signals

After turning off the engine, measure the resistance across the IAT sensor terminals. Later steps will be based on this baseline reading.

Read more about How to Test Turn Signal Relay with Multimeter?

Step 4: Expected Reading at 20°C

A reading of approximately 37K ohms should be observed at an ambient temperature of 20 degrees Celsius (°C). A temperature reading validates the sensor’s functionality.

Step 5: Check Resistance at 30°C

When the temperature reaches 30°C, you should expect a resistance around 24K ohms. The sensor is accurate at higher temperatures, according to this assessment.

Step 6: Reconnect Electrical Connector

Ensure the electrical connector on the IAT sensor is securely connected after measurements. Performing sensors accurately requires proper connection.

Read more about How to Test IAC Valve with Multimeter?

Step 7: Idle Engine for 20 Minutes and Monitor Temperature Increase

Ensure the engine is idle for 20 minutes. This duration stabilizes the engine’s operating temperature. Monitor the gradual rise in engine temperature. Hope now you know how to test IAT sensor with a multimeter.

Read more about How To Test a Temperature Sensor With a Multimeter?

Step 8: Turn Off the Engine, Disconnect Connector, and Measure Resistance Again

When the engine temperature reaches significant levels, turn it off. Take a measurement of resistance across the sensor terminals immediately after disconnecting the electrical connector. The engine’s residual heat is eliminated by this sequence of steps.

Step 9: Expected Reading at Elevated Temperatures

As the temperature reaches approximately 90°C, the IAT sensor’s resistance should read around 2.8K ohms. This reading confirms the sensor’s accurate performance at elevated temperatures.

Step 10: Final Confirmation at High Temperature

Approaching 100°C, the expected resistance should stabilize at approximately 2K ohms. This final step validates the sensor’s consistent and reliable readings even under high-temperature conditions.

Step 11: Validate Sensor Performance

Throughout the testing process, review the Digital Multimeter readings. A consistent and matching reading with the expected values outlined in the previous steps confirms proper Intake Air Temperature sensor operation.

Best Digital Clamp meter offered by Fluke.

Multimeter test of IAT sensor power circuit

” IAT Sensor Voltage Testing”

Step 1: Prepare for Testing

The vehicle must be turned off and the ignition key removed before performing the Multimeter test. In this way, electrical interference is prevented during testing.

Step 2: Access the IAT Sensor

Locate the Intake Air Temperature sensor. IAT sensors are usually located near air intake manifolds. IAT sensor terminals can be accessed by gently disconnecting the electrical connector.

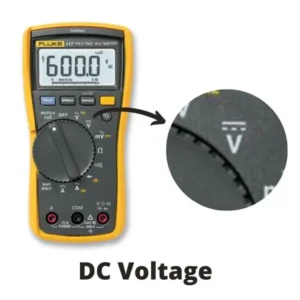

Step 3: Set Up the Multimeter

You should use a voltage (V) setting suitable for DC voltage measurements. Choose a range that fits IAT sensor voltage levels. Typically, 20V is appropriate.

Step 4: Probe the IAT Sensor Power Circuit

The IAT sensor is powered through two terminals. They are usually marked “+V” (positive voltage) and “GND” (ground). Make sure the Multimeter probes are securely connected to these terminals.

Step 5: Read and Interpret the Voltage

An assistant should turn on the ignition without starting the engine while the Multimeter probes are in place. Check the voltage across the power circuit of the IAT sensor using a Multimeter.

The voltage reading should be stable and appropriate, depending on the make and model of the vehicle. If the Intake Air Temperature sensor wiring is correct, the digital multimeter should show 4.5 to 5 V. Multimeter with a sensor.

Multimeter readings are substantially different from the expected voltage or no voltage at all could indicate an issue with the IAT sensor power circuit. Ahh, I’m sorry, but you need to call an automotive technician because the issue might be with your car wiring.

Luckily we have made a guide on how to test car wiring with a multimeter.

IAT Sensor Ground Circuit Testing:

- Switch off the car.

- Use the black lead of the Digital Multimeter to connect to the ground wire of the Intake Air Temperature sensor and read information to the battery voltage.

- Without starting the engine, turn on the ignition switch.

- If the INTAKE AIR TEMPERATURE sensor wiring connects to the ECU, the meter should read 12V.

- The car’s ignition should be off.

Bad IAT Sensor Symptoms:

If the IAT sensor is not working correctly, it can lead to various issues, including poor fuel economy, engine misfiring, increased emissions, and difficulty starting the engine. If you experience any of these issues, it is essential to have your IAT sensor checked as soon as possible.

A malfunctioning Intake Air Temperature (IAT) sensor can lead to various issues in your vehicle’s performance. Here are seven common symptoms of a bad IAT sensor:

- Poor Fuel Economy: Incorrect temperature readings from the IAT sensor may cause a poor fuel-to-air ratio. Consequently, fuel consumption increases and fuel efficiency decreases.

- Rough Idling: If the IAT sensor provides inaccurate temperature data, the ECM may adjust the air-fuel mixture incorrectly, causing the engine to idle roughly or even stall.

- Lack of Power: An incorrectly functioning IAT sensor will result in an incorrect air-fuel mixture, resulting in reduced engine power.

- Engine Knocking or Pinging: Detonation can occur when there is an incorrect air-fuel ratio caused by a bad IAT sensor. As a result, the engine could be damaged.

- Check Engine Light: Check engine light illuminates when the IAT sensor fails, triggering the vehicle’s onboard diagnostics system. It can help to retrieve the trouble code.

- Difficulty Starting: When the IAT sensor provides incorrect temperature readings, the engine may not start, especially during extreme weather.

- Emissions Issues: A malfunctioning IAT sensor can produce inaccurate temperature data, resulting in increased emissions.

Furthermore, by testing the IAT sensor using a multimeter, you can be sure that your sensors are working correctly and diagnose any underlying issues. With the right tools and knowledge, testing an IAT sensor is a relatively quick and easy process. Although, with this guide, you can be sure that your IAT sensor is functioning correctly and that your vehicle will run efficiently.

Conclusion:

Testing the IAT sensor is essential to ensure it is working correctly and that the engine can run efficiently. Using a multimeter, technicians can quickly diagnose issues with the IAT sensor before they become more serious. With proper testing and maintenance, you can ensure your vehicle runs as it should and that your fuel economy is optimized. I hope now you know how to test IAT sensor with a multimeter.

FAQs:

What is an IAT sensor?

An IAT sensor (Intake Air Temperature Sensor) helps to measure the temperature of the air passing through the intake system of a vehicle. So, this data ensures that the engine runs optimally and that your fuel economy is optimizing.

What should the readings be on an IAT sensor?

At 20 degrees Celsius, the resistance should be 37K ohms. In addition, the resistance should be 24K ohms at 30 degrees Celsius, 2.8K ohms at 90°C, and 2K ohms at 100°C.

What are the symptoms of a bad IAT sensor?

A bad IAT sensor can lead to poor fuel economy, engine misfiring, increased emissions, and difficulty starting the engine. If you experience any of these issues, it is essential to have your IAT sensor checked as soon as possible.

How do you know if your IAT sensor is bad?

You can test the IAT sensor using a digital multimeter. If your readings do not match the expected values, it may be time to replace the IAT sensor. It is also essential to check the wiring of the IAT sensor to make sure it is connecting correctly. If there is a problem with the wiring, it must be addressed before replacing the sensor.

What happens if you don’t replace a bad IAT sensor?

If the bad IAT sensor is not replaced, it can lead to further damage and cause your engine to run inefficiently. Besides, it can result in additional engine damage and decreased fuel economy. It is essential to address any issues with the IAT sensor as soon as possible.